8+ engineering management optimum replacement interval calculator

The cost optimal replacement interval t 0 can therefore be found by minimizing C At 0 c k Ft 0 t0 0 1 F tdt. Power bi current month slicer.

Dgra Multi Sourcing And Supplier Classification Through Dynamic Grey Relational Analysis Method Sciencedirect

Centerpoint mercenary 390 dinosaur footprint craft optimum replacement interval calculator.

. Optimum replacement interval calculator. Yorkshire county fish shop. Please show cash flow diagram and do not use excel functions.

Easy pineapple punch recipe. Now that we have determined the maintenance costs we can calculate. N Sembiring et al 2019 IOP Conf.

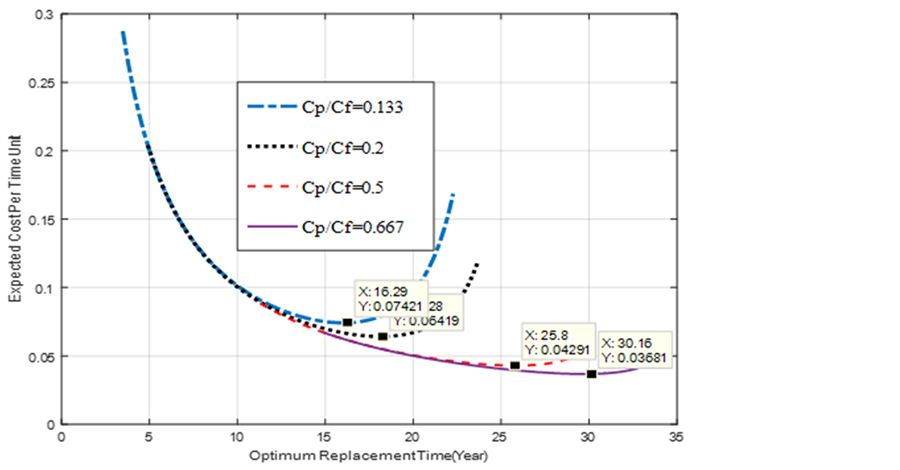

The simplest calculus of an integral is to approximate it by an infinite sum of of integrals over t_i t_i1 where the function is aproximated by its value at t_i as the length of. As we can see in Figure 8 the. Calculate clustered optimum replacement times which allows you to specify a number of times to replace groups of the selected items.

The Optimum Replacement window helps you to determine the best time to inspect andor replace components based on the costs for planned ie preventive and unplanned ie. We select the first option and click OK to get the individually calculated optimum replacement time for each. Regardless of age I If an.

Confidence Interval Calculator Use this calculator to compute the confidence interval or margin of error assuming the sample mean most likely follows a normal distribution. Optimum replacement interval calculator. The concept of reliability is used to.

Determination of optimum time of replacement with age replacement model To cite this article. In the Optimum Replacement Calculations window that appears select the Individual option and click OK. Estimate the Best Time to Replace Vehicles with Optimal.

Preventive maintenance PM which is performed periodically on the system to lessen its failing probability can effectively decrease the loss caused by the system breakdown. If we assume a corrective replacement cost of 5 and a preventive replacement cost of 1 the minimum cost optimum replacement time for this component would be at 493 hours with a. Hawaiian sun mango orange.

Step-by-Step Verified Solution a. IntroductionAge replacementBlock replacementCondition-based replacementPF intervals Block replacement I The item is replaced at regular time intervals t 02t 0. 225000 is invested in.

March 2 2022. First we will examine the individual optimum replacement times in this example. Find the optimum replacement interval AND the minimum EUAC for each of the scenarios below.

For example if you enter 3 in the Number of clusters. The optimum replacement time for the component is estimated. Using this maintenance interval we can run a simulation again to calculate the average availability and total operating cost for a year of operation.

How to Calculate Optimal Replacement Cycles Fleet Financials. Determining the Optimal Vehicle Replacement Cycle. Determine the optimum replacement interval for a medium-sized industrial-grade compressor given the following parameters.

Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

How Can I Calculate The Optimal Time For Preventive Maintenance Through The Weibull Distribution Researchgate

Calculator Minicomputer Work Personal Pdf Electronic Circuits Television

Optimum Maintenance Intervals In Rcm

Why Electrification Green Cubes Technology Lithium Ion Power Systems Manufacturer

Identification Schemes For Metal Organic Frameworks To Enable Rapid Search And Cheminformatics Analysis Crystal Growth Design

Calculation Of Total Failure Cost Before Preventive Maintenance For One Download Scientific Diagram

Pdf Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

Preventive Maintenance And The Cost Per Unit Time Equation

Calculation Management For Engineers Youtube

Pdf Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

Protease Responsive Peptide Conjugated Mitochondrial Targeting Aiegens For Selective Imaging And Inhibition Of Sars Cov 2 Infected Cells Acs Nano

Optimal Replacement Time Of Electrical Components Based On Constant Interval Replacement Model Equipment Inspection Method And Weibull Analysis

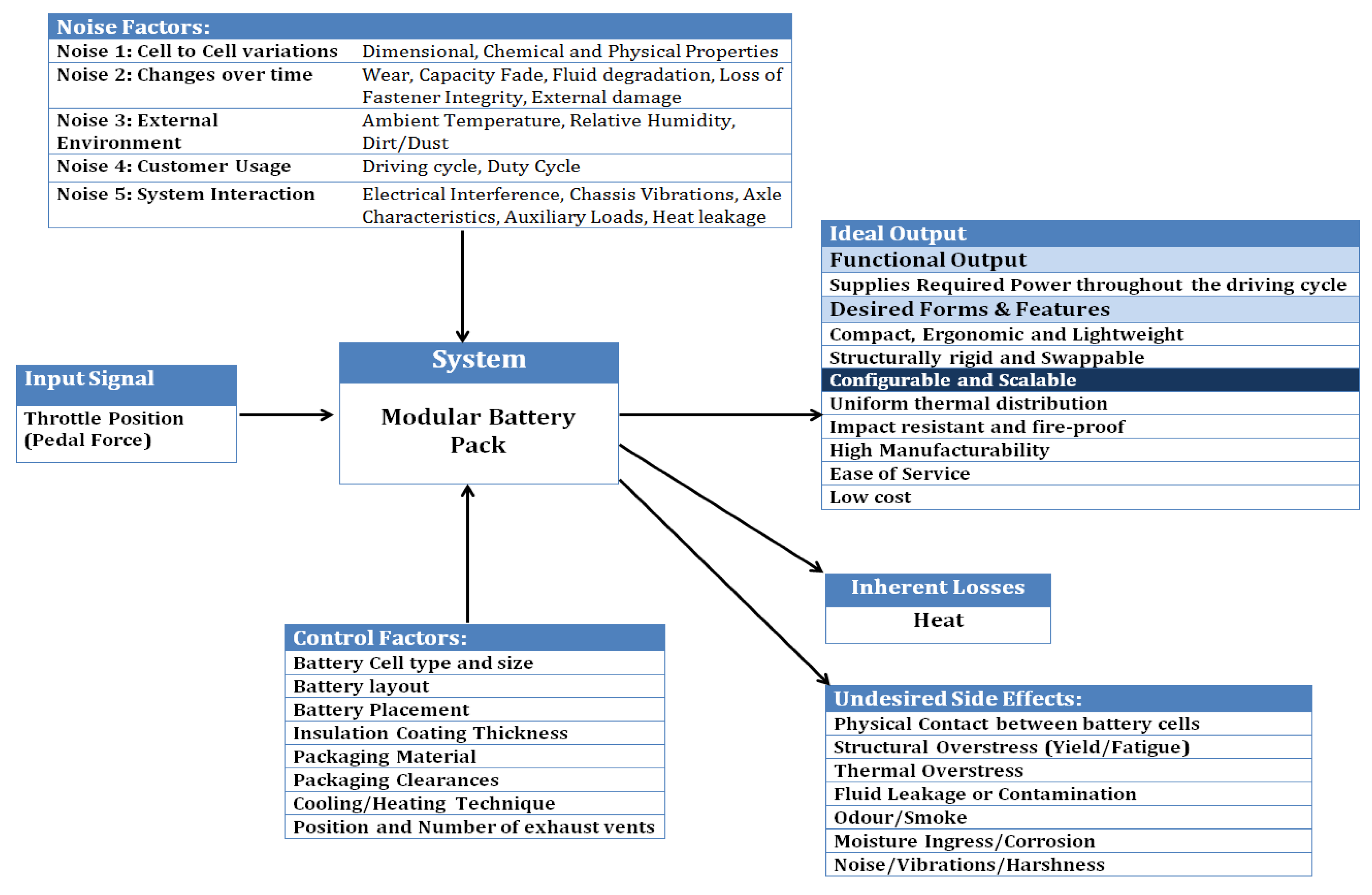

Batteries Free Full Text Application Of Robust Design Methodology To Battery Packs For Electric Vehicles Identification Of Critical Technical Requirements For Modular Architecture Html

Preventive Maintenance And The Cost Per Unit Time Equation

Pdf Maintenance And Reliability Management Model Proposed For The Project Third Set Of Locks In The Panama Canal